-

Featured User: kurt

Open-source hardware project hosting is my passion. I spend most of my free time building neat gadgets or planning what I'll build next. I love building things, and I want to make Open Hardware Hub a place that inspires others to build, ...

-

Updates 2013 February 18

It's been a while, hasn't it? Well, that's ok because we've got a lot of updates to talk about. Most of these have been effective on the site fora couple weeks now. A few may or may not be active when this article gets posted, but they'll certainly be applied in the ...

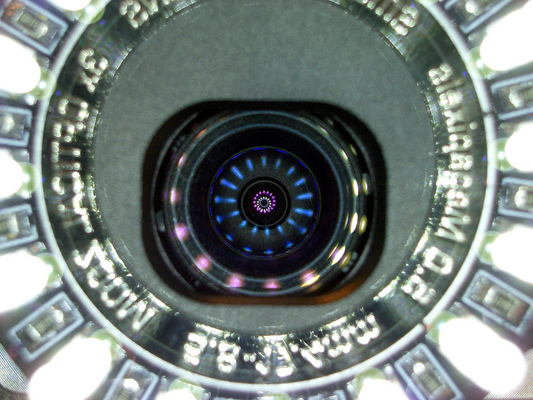

Tiny LED ring-light

By: madworm

How to get light onto objects that are close to the lens of a small digital camera.

Download project description w/o images

Download project description w/ images

Files

- LED-ring__schematic.pdf - Schematic

Bill of Materials

| Qty | Part # | Description | Schematic ID | Source | |

|---|---|---|---|---|---|

| 1 |

|

AO3400A | MOSFET N-CH 30V 5.7A SOT23 - AO3400A | Q1 | Source |

| 1 |

|

ERJ-6GEYJ151V | RESISTOR, 0805, 150R 5%, 0.125W | R17 | Source |

| 1 |

|

ERJ-6GEYJ104V | RESISTOR, 0805, 100K 5%, 0.125W | R18 | Source |

| 2 |

|

ERJ-3GEYJ102V | RESISTOR, 1K, 100MW, 5% | R18,R19 | Source |

| 1 |

|

GRM21BR61E475KA12L | CAPACITOR, 0805, 4.7UF, 25V | C1 | Source |

| 16 |

|

ERJ-6GEYJ680V | RESISTOR, 0805, 68R 5%, 0.125W | R1-R16 | Source |

| 16 | LED PLCC2 3528 | Colour temperature: 6000k Vf: 3.2V @ 25mA | D1-D16 | ||

| 2 | RS-282G05A3-SM RT | SWITCH TACTILE SPST-NO 0.05A 12V | SW1, SW2 | Source | |

| 1 |

|

ATTINY13-20SU | IC, 8BIT 1K FLASH MCU, SMD, SOIC8 | IC1 | Source |

Download BOM w/o images

Download BOM w/ images

Steps

1. Measure twice - order PCB once

Although having PCBs made is pretty affordable nowadays, it sucks to receive boards that won't fit. And let's not forget about the time-penality.

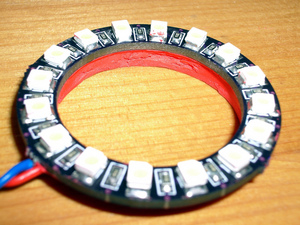

2. Separate the boards and upload code

- Snap the break-away tabs with an old wire-cutter and clean up the edges with a file or sandpaper.

- Upload the PWM firmware to the micro

- Dry-fit the ring and measure how much length of wire you need

- Attach the wires

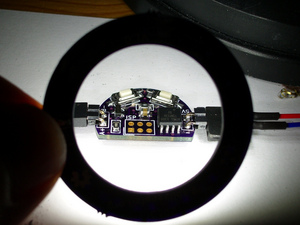

3. Use Sugru to make a tight-fitting retaining ring

The inner diameter is slightly over-sized. That allows for some manufacturing tolerances and should help to avoid scratching the plastic case of the camera.

To keep the board perfectly centered in place and away from the plastic, Sugru rubber is used to form a retainer ring. It grips to the stationary part of the objective.

To prevent Sugru from permanently sticking to the case during the molding-phase, cling-film is used inbetween it and the case. Care must be taken to get a wrinkle-free layer. Make sure to let the rubber cure for a full 24h hours. It may appear solid on the outside after several hours, but will still be malleable inside. If the board is pulled of too early, Sugru will tear inside and fail to do the job.

A wax-based release agent might work as well, but it comes with the risk of running into the objective and coating the lenses.

4. Take well lit macro shots!

But let's not stop here!

A source of illumination that doesn't block direct line-of-sight is also helpful in microscopy, SMD inspection, looking at stamps...

Download steps w/o images

Download steps w/ images

Revisions

3 -

2 - Added Gerber files.

1 - Initial project release

Add revision

blog comments powered by Disqus

Back